The EV charging connector manufacturer required an automated machine to complete the terminal assembling processing automatically, which is to improve the efficiency and productivity, At the same time, reducing the time and labor required. Additionally, The Automated 6.0 mm EV Charging Socket Assembling Machine can improve the accuracy and consistency of each assembly, reducing the likelihood of errors or defects.

The automated 6.0 mm EV charging socket assembling machine is a high-tech device designed to match highly with the manufacture requirements. The machine is capable of assembling charging sockets automatically, from the materials loading to the socket completed. The whole processing are automatically running. It is equipped with advanced technology, including sensors, force test and other automated features, that ensure precise and accurate assembly of each charging socket. The machine is easy to operate and maintain, the automated 6.0 mm EV charging socket assembling machine is a powerful tool that can help businesses stay competitive in the growing market for electric vehicles.

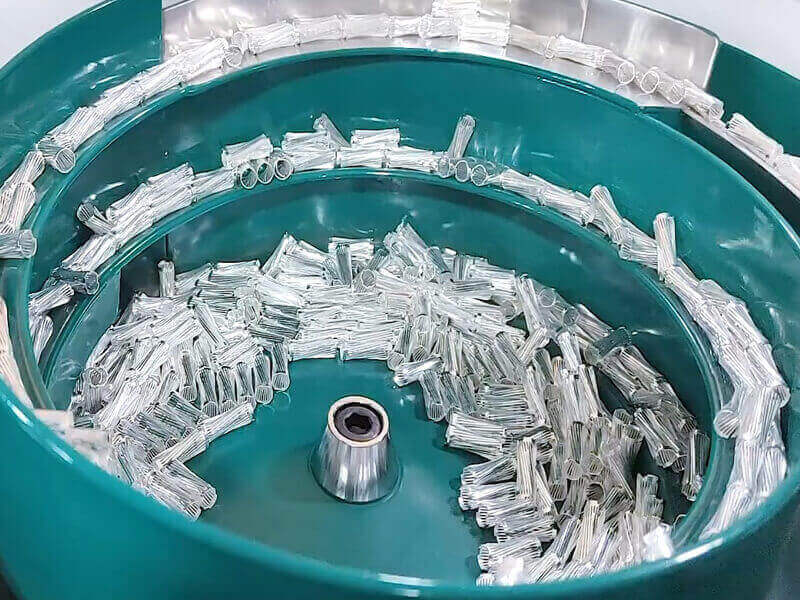

The EV charging socket assembling machine is a cutting-edge device that boasts eight workstations arranged in a rotary table configuration, ensuring maximum efficiency in the manufacturing process. It features three feeding bowls, catering to the assembly of female terminals, springs, and retainer rings. The automated machine incorporates advanced technology, including material detection, assembly, riveting, trial plug-in, product rejection, and output of flawless finished terminals.

The EV charging socket assembling machine is equipped with a special loading system and positioning part for each individual component, ensuring precise and accurate component loading and positioning. This is a crucial step in ensuring flawless assembly and maintaining the coaxiality of each component. The loading system streamlines the process of loading components onto the machine, while the positioning part guarantees exact positioning, resulting in seamless assembly and flawless finished terminals.

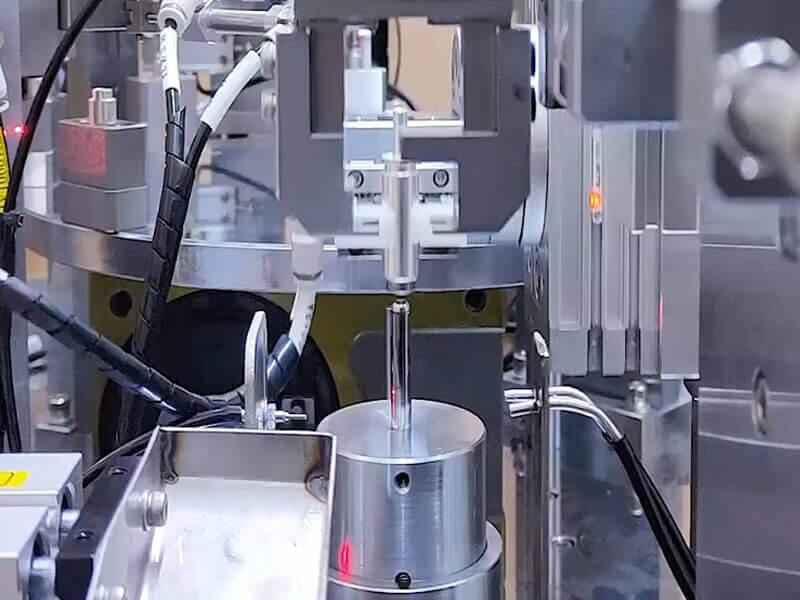

The EV charging socket assembling machine incorporates a plug-in test workstation that is specifically designed to ensure flawless assembly of each charging socket. This workstation features a servo motor and cam structure, allowing for precise and accurate testing of the socket’s plug-in functionality. The servo motor provides high-speed and efficient movement, while the cam structure enables smooth and consistent testing.

The plug-in testing workstation on the automated EV charging socket assembling machine offers unparalleled flexibility, allowing users to set the testing parameters according to their specific requirements. The touch screen interface makes it easy to adjust the testing numbers for each charging socket, accommodating the unique testing requirements of different terminals and connectors. By offering this level of customization, the machine ensures the highest level of accuracy and reliability, regardless of the type of charging socket being produced.

At the end of the automated EV charging socket assembling machine, similar to other new energy connector assembly machines, the final testing workstation is a critical component. However, in the case of the 6.0 mm EV charging socket assembling machine, the weight lifting test workstation is the key function, ensuring each connector’s insertion and extraction force meets the required standards. This feature guarantees that each charging socket functions seamlessly with electric vehicles, reducing the risk of defects and failures. Additionally, the machine is equipped with a reject zone and an output area for separating bad products from the good ones, ensuring only high-quality finished products are delivered to customers. Overall, the weigth lifting test workstation and reject zone are essential features of the automated EV charging socket assembling machine, providing businesses with the confidence to produce reliable and high-quality electric vehicle charging sockets.

Please provide us with your information and a brief description of your project. Our team will reply you within 8 hours.